Industry

Highlights

- Battery giga factories are rapidly emerging as the backbone of the clean energy transition, producing energy storage units that will power electric vehicles, stabilize renewable grids, and accelerate decarbonization. Yet, behind this promise lies an unspoken challenge: e-waste generation on an unprecedented scale.

- From electrode coating scraps to rejected cells and aging test modules, gigafactories produce tons of hazardous and valuable waste daily. If unmanaged, this undermines the sustainability mission they were built to serve.

- This paper presents a holistic framework for sustainable e-waste management in gigafactories, highlighting reduction, reuse, recycling, and digital traceability as core pillars. Drawing inspiration from global best practices and aligning with international regulations, we argue that waste management is not a cost center, but a value-creating opportunity for the circular economy.

On this page

The Paradox of Progress

“As Fatih Birol of the IEA has often emphasized, clean energy solutions must avoid creating hidden footprints. A gigafactory without e-waste management is like building a solar farm that leaks oil.”

Gigafactories symbolize the scale and ambition of the clean mobility revolution. These mega-plants, often spanning millions of square feet, churn out battery cells at gigawatt-hour capacity annually. By 2030, more than 400 gigafactories are expected worldwide.

However, this massive production surge is coupled with rising waste streams. Studies suggest that 5–10% of initial cell production ends up as scrap, particularly during ramp-up phases. The irony is striking - facilities designed to cut greenhouse gas emissions risk becoming sources of toxic waste pollution if e-waste is not managed responsibly.

“The need is clear, a new sustainability lens for giga factories, focused not only on output but also on responsible waste stewardship”

Anatomy of E-Waste

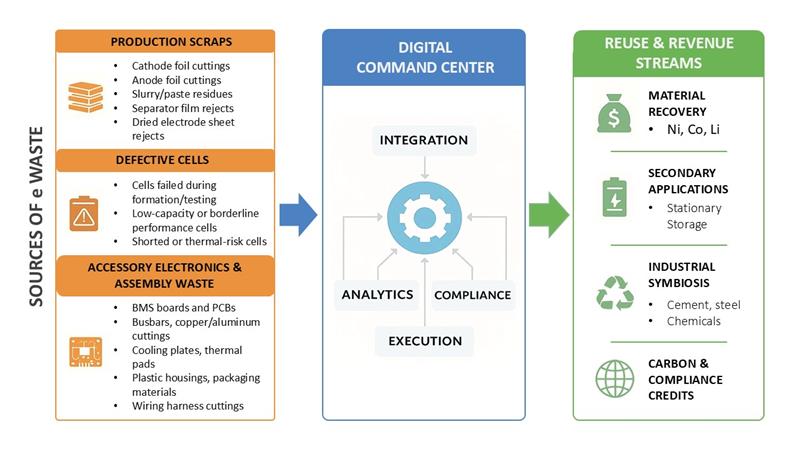

The Anatomy of E-Waste in a Gigafactory

Unlike conventional electronics, gigafactory e-waste is chemically active, flammable, and resource rich. Key categories include:

- Production Scrap

- Cathode/anode foils (nickel, cobalt, manganese, lithium)

- Separator films, electrolyte residues, slurry waste

- Quality Rejects

- Cells/modules failing cycle-life or safety testing

- Defective batches from coating, calendaring, or formation

- Ancillary E-Waste

- Battery Management System (BMS) boards

- Sensor wiring, IC chips, lab instruments

- Packaging & Containment Waste

- Contaminated plastics, solvents, foils

- Hazardous drums and PPE

A visualization of waste streams reveals a “hidden mine” of critical raw materials (CRMs), often discarded in forms that are both hazardous and economically valuable.

Risks of Neglect

"In the words of António Guterres (UN Secretary-General), “Humanity is waging war on nature. This is suicidal. Nature always strikes back, and it is already doing so with growing force and fury.”

Poorly managed gigafactory waste creates a quadruple risk:

Environmental – soil leaching of lithium salts, water contamination by heavy metals, and greenhouse gas emissions from burning waste.

Safety – thermal runaway risks from improperly discarded cells, fires during transport, toxic gas emissions.

Financial – loss of scarce materials like cobalt and nickel, escalating disposal costs.

Regulatory – penalties under frameworks such as EU Battery Regulation (2023/1542) and India’s E-Waste (Management) Rules, 2022.

Stewardship Imperative – Pathways to Responsibility

Christiana Figueres (Architect of the Paris Agreement) says, “We must move from incremental to exponential action, from responsibility to stewardship, if we are to ensure a safe and stable future.”

E-waste in a gigafactory demands a layered response. It starts with reduction at source, where predictive analytics and precision processes cut down scrap before it accumulates.

What remains should be redirected and reused borderline - cells, components, or electronics, finding purpose in less demanding applications instead of being discarded.

The rest must go through recycling and recovery, where safe pre-processing and specialist partners convert hazardous leftovers into valuable streams of lithium, nickel, cobalt, and copper.

At every stage, digital traceability ensures accountability QR tagging, passport-enabled reporting, and real-time dashboards that keep operations transparent and compliant. Together, these pathways create a living framework of responsibility, aligning industrial ambition with environmental duty.

The Digital Nerve – A Digital Spine for Circularity

Satya Nadella, CEO of Microsoft says, “Digital technology is the most malleable resource at our disposal to address the world’s most pressing challenges.”

E-waste in giga factories is too complex to be handled by static plans; it requires a living platform that continuously senses, learns, and adapts. The need is a sustainability command center: a digital backbone that unifies waste tracking, compliance, and optimization. Instead of static oversight, factories require predictive intelligence that anticipates risks and enables action in real time.

How It Works

- Integration: IoT sensors, ERP/MES systems, and recycler data combine into a live map of material flows.

- Analytics: AI models forecast scrap, detect process inefficiencies, and identify recovery potential.

- Compliance: QR codes, blockchain records, and battery passports ensure global regulatory alignment.

Decision Intelligence

Dashboards present key metrics scrap rates, recovery yields, compliance scores, carbon impact, and cost savings in one consolidated view. Optimization engines weigh recycling costs against recovered value, while industrial symbiosis directs by-products into steel, cement, and chemical industries, extending value beyond the gigafactory.

Needed Digital Enablers

- Real-time segregation of waste streams

- Predictive analytics and AI models

- Traceability and compliance layers

- Circular economy dashboards

- Optimization engines

- Industrial symbiosis linkages

The sustainability command center evolves into a sustainability operating system, transforming e-waste from a liability into a source of resilience, revenue, and regulatory assurance across all battery domains.

Zero-Waste as Destiny - E-Waste as a strategic revenue stream

In the words of Ellen MacArthur (Founder, Ellen MacArthur Foundation – Circular Economy), “Waste is just a resource in the wrong place.”

Gigafactories should no longer view e-waste as a liability. Channelized effectively, these streams evolve into profitable revenue models that strengthen both sustainability and competitiveness.

- Material Recovery: Cathode/anode scrap accounts for 5–10% of production volume. At current metal prices, recovered cobalt and nickel can yield USD 0.6–12/kg. A 20 GWh gigafactory discarding ~8% electrode scrap could unlock USD 150–200 million annually.

- Secondary Applications: Borderline cells can power stationary storage or consumer devices, extending value by 20–30% compared to disposal.

- Electronics & Ancillaries: BMS boards and sensors contain rare earths and copper worth USD 4,000–6,000/ton.

- Industrial Symbiosis: Plastics, foils, and solvents can be redirected into cement, steel, or chemical industries, reducing disposal costs by 20–25% while generating shared revenues.

- Carbon and Compliance Credits: Digital platforms allow monetization of circularity and carbon credits, adding service-based income streams.

By reframing waste as an asset, gigafactories can transform circularity into a strategic revenue lever delivering resilience, regulatory compliance, and profitability.