Industry

Services

Highlights

- The need for product customization in aerospace and defense industries makes it difficult to measure the profitability metric accurately.

- Three strategies that can improve the accuracy of profitability measurement are: streamlining the end-to-end process, maintaining a common digital thread through the life of the product and across systems, and proper cost allocation.

- The use of the modern-day production lifecycle management (PLM), enterprise resource planning (ERP), and manufacturing execution system (MES) tools supplemented with AI can help streamline the end-to-end (E2E) process.

On this page

Profitability metric

As the aerospace and defense industry moves towards more customized manufacturing, measuring profitability accurately has become challenging.

This is because customization entails many options and variant configurations. Many organizations struggle because, with sales processes not tightly integrated into manufacturing, many cost components get spread across airplanes based on thumb rules instead of their direct allocation to individual aircraft.

Business leaders are looking for means to measure the profitability of aircraft manufacturing more accurately and use that information to optimize the sales of high margin products. The lack of a solution that integrates the complete lifecycle processes of an aircraft with common threads and standard harmonized processes across sites makes this very difficult. The key to achieving an accurate profitability metric is to record the sales and costs in the same structure and integrate the costs incurred through the product lifecycle from demand to production, maintenance, and service. Three strategies can improve the accuracy in profitability measurements– streamlining the end-to-end process, maintaining a common digital thread through the life of the product and across systems, and proper cost allocation.

Streamline processes

The use of modern-day production lifecycle management (PLM), enterprise resource planning (ERP), and manufacturing execution system (MES) tools supplemented with AI can help streamline the end-to-end (E2E) process.

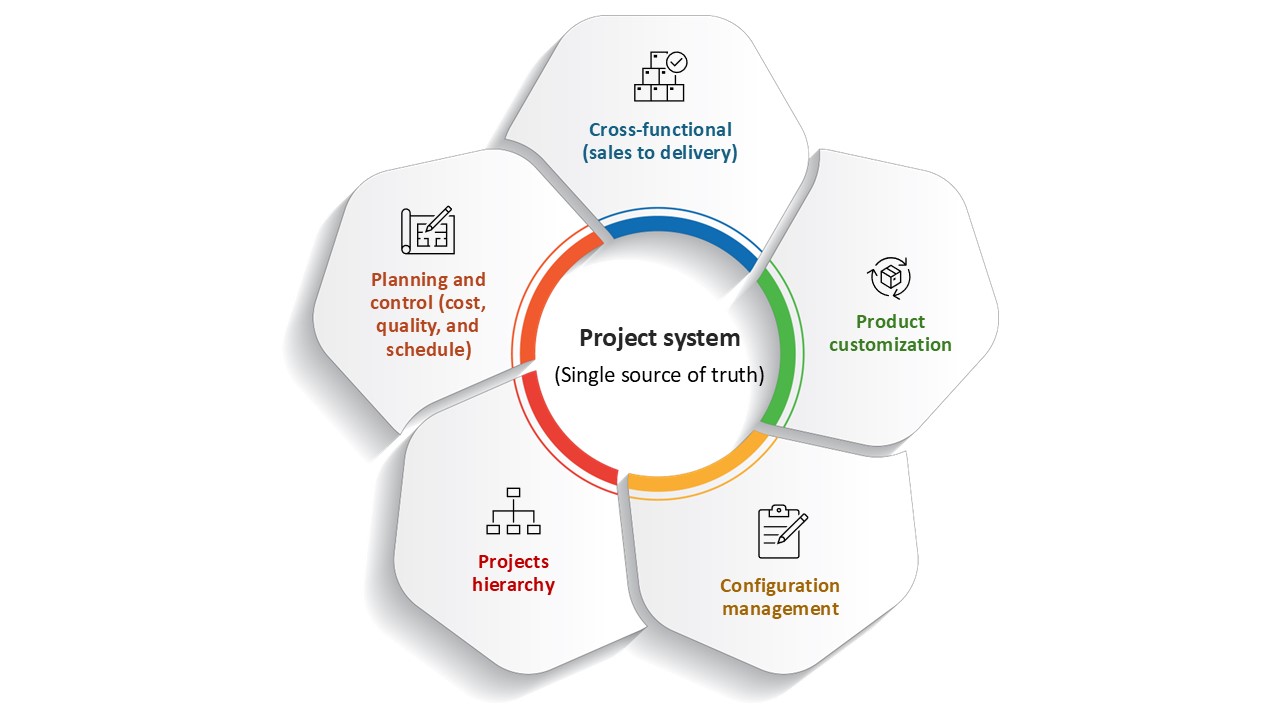

The key to meeting the desired business goals for production and aftermarket is to define the relevant bill of materials (engineering, manufacturing, sales, service, and super bill of materials), maintaining a single source of truth (PLM or ERP), and making consistent data available for all process owners, when needed.

It takes significant effort and several months after aircraft sales for finance to collaborate with the departments concerned to determine the actual cost of building an airplane. This delay in accurate cost estimation can lead to reduced margins and lost opportunities for selling more profitable options and variant configurations (eg, warranty options, service plan, choice of interiors) since at the time of sale, the rule of thumb and non-standard tools are used for cost and pricing calculations. When appropriate data governance measures are put in place and appropriate tools used, there is no reliance on heuristics for estimates.

When the sales department possesses the full catalog of products and services offered by an organization along with their associated costs, pricing, and timelines, the market demand becomes the trigger to produce parts in the required amounts based on the applicable manufacturing strategy. The material requirement planning (MRP) runs based on the demand forecast can follow and the decisions on whether to procure or manufacture a particular component, product version to be produced, whether to increase or decrease the production capacity of certain equipment, can be made in a timely manner.

Using technical platforms such as PLM, ERP, and MES, the processes can be streamlined and integrated so that the costs of making an aircraft and the associated revenue can be measured in a more objective way.

Common thread

A common digital thread between PLM and ERP simplifies the OEM’s task of identifying ‘as designed’, ‘as built’, ‘as delivered’, and ‘as maintained’ product configurations and verify compliance with mandatory regulations.

A typical commercial aircraft (eg, Airbus A350, Boeing 787) is made of millions of complex parts and though the standard cost for all components and minor or major assemblies of an aircraft is broadly available on the basis of historical data and overall business strategy, the actual cost of building an aircraft would vary considerably depending on the different configurations required.

Apart from the variation in configuration, the costing is complex also because of evolving manufacturing processes, changing design requirements (due to regulatory and market needs) and supply chain disruptions. AI predictive analytics can help bridge the gap between cost estimates and actuals by utilizing not only the large volume of available historical data (operating technology and information technology) but also the evolving global business ecosystem and assisting in decision-making. These AI models can make use of a company’s proprietary data along with publicly available data for the entire business ecosystem, to draw insights and enable better planning and cost estimation.

Apart from safety, traceability, and regulatory reasons, it is also essential to manage the configuration of a complex product like an aircraft throughout its lifecycle for accurate cost assignment. Having a common digital thread right from the inception of new design to manufacturing, sales or customer delivery, in-service maintenance and until the product’s retirement (end of useful life) helps in keeping track of the configuration and assigning costs appropriately for all components and activities throughout the product’s lifecycle.

Assign cost aptly

Instead of using thumb rules for spreading cost across airplanes for all low-value components, project-based allocation can be used to capture the cost for some components such as fuel and paint.

The sale of options on an aircraft should be tied to manufacturing using project-based manufacturing, which can be used to build a bridge between the two functions in such cases.

Some cost components such as paint, fuel, and fasteners are spread across multiple aircraft with different thumb rules to divide the cost. Only in the case of paint, the tail number being worked at a particular workstation is tracked, enabling accurate quantity to be allocated to the specific tail number, thereby ensuring accurate cost capturing.

Another thing to note is that the costing process is not completely done immediately after an aircraft is sold. The industry tracks maintenance and repair work on aircraft for different reasons, being able to be tracked and linked to the aircraft tail number. Similarly, the upfront sales process and revenue recording can be integrated seamlessly into the way costs are recorded.

Harmonize processes

It is important to standardize and harmonize the optimized processes across the organization.

It is also critical to have seamless integration between business functions to ensure consistent information flow and holistic transformation (see Figure 1).

The capability to accurately measure the profitability metric will allow manufacturers to identify, recommend, produce, and sell cost-efficient configurations to customers.

A comparative analysis of different processes used in producing different variants of a part, product, or assembly will enable the identification of optimal processes from various perspectives like cost, agility, and efficiency. Consequently, there will be a reduction in the total number of processes used in an organization due to the standardization, harmonization, and adoption of effective processes across plants and variant configurations.

Adopting the discussed strategies will not only improve the accuracy of profitability metric but also the metric itself.