Services

Highlights

- Dark factories are the next stage in smart manufacturing, characterized by highly automated, AI-driven operations with minimal human presence, aiming to enhance efficiency, quality, safety, and sustainability through the integration of physical and AI agents.

- The transition to dark factories addresses business competitiveness, workforce shortages, and operational imperatives, but requires overcoming challenges related to investment, ecosystem readiness, cybersecurity, regulatory compliance, and organizational change management.

- Successful dark factory implementation delivers significant business and societal benefits—improving productivity, cost-effectiveness, and resilience—while demanding robust strategy, architecture, ecosystem collaboration, and a focus on responsible AI and workforce transformation.

On this page

Why dark factories?

In today’s rapidly evolving manufacturing landscape, the concept of “dark factories” is gaining momentum as organisations seek to address critical business, workforce, and operational challenges. Driven by the need for greater competitiveness, scalability, and sustainability, dark factories leverage advanced AI agents and autonomous systems to optimise production, enhance energy efficiency, and enable highly adaptive manufacturing processes.

Business drivers - Ever increasing priorities and needs of manufacturing operations like competitiveness increasingly demand for faster time‑to‑market, coupled with scalability, sustainability and more importantly safety of worker (Hazardous operations line handling of chemicals in process industries, heavier parts handling in automotive assembly stations, confined space working for maintenance activities and remote areas of operations like STP, ETP etc.,) and assets. Ever-increasing demands to reduce manufacturing cost by optimising utilities cost, productivity, and improving production capacities with a smaller factory footprint.

Workforce realities - Global labour markets face chronic shortages of skilled shop‑floor personnel, rising safety expectations, and the need to elevate human roles away from repetitive tasks. During the smelting process, hazardous activities such as transferring or pouring molten metal with ladles and cranes pose considerable safety risks to workers. The intense radiant heat emitted by furnaces and hot metal further exacerbates the unsafe working conditions. Additionally, the operation of loud machinery and associated processes produces substantial noise and vibration. In dark factories, human-dependent activities will be offloaded to Humanoid robots, etc., significantly reducing safety risks. Humans will also shift from direct handling to supervision and governance from control rooms. At the same time, AI agents synchronise production, prescribe process corrections, and interact with non‑manufacturing functions to keep operations flowing. This transition improves worker safety in hazardous activities, such as heat treatment, chemical processing, and operations at rolling mills and smelters.

Operational imperatives – Operations in industries like discrete manufacturing, such as injection molding, automotive, and medical devices, involve human-dependent activities like assembly, quality inspection, and setting optimal process parameters, which are prone to errors, leading to quality defects and reduced throughput. Quality (“first time right”), throughput optimisation, quick line changeovers for multi‑model production, and footprint efficiency (more output per unit area) are increasingly non‑negotiable in these industries. Dark factories will enable round‑the‑clock operations, enabled by autonomous equipment and real‑time analytics, create a step‑change in overall equipment effectiveness (OEE) and productivity. Dark factories achieve this by marrying machine‑to‑machine (M2M) communication with AI‑orchestrated production, e.g., automatically resequencing CNC orders based on availability of downstream equipment, quality parameters of upstream process, process parameters conditions (such as coolant & lubricant conditions, tool life, etc.)when outputs deviate, or digitally twin‑driven planning and monitoring that corrects drift before defects accumulate.

Several barriers, including high capital investment, ecosystem readiness, supply chain disruptions, and regulatory compliance, accompany these drivers. Organisations should view these as program risks to be managed through phased adoption, strong governance, and close collaboration with partners, not as obstacles to transformation.

Journey to darks-out

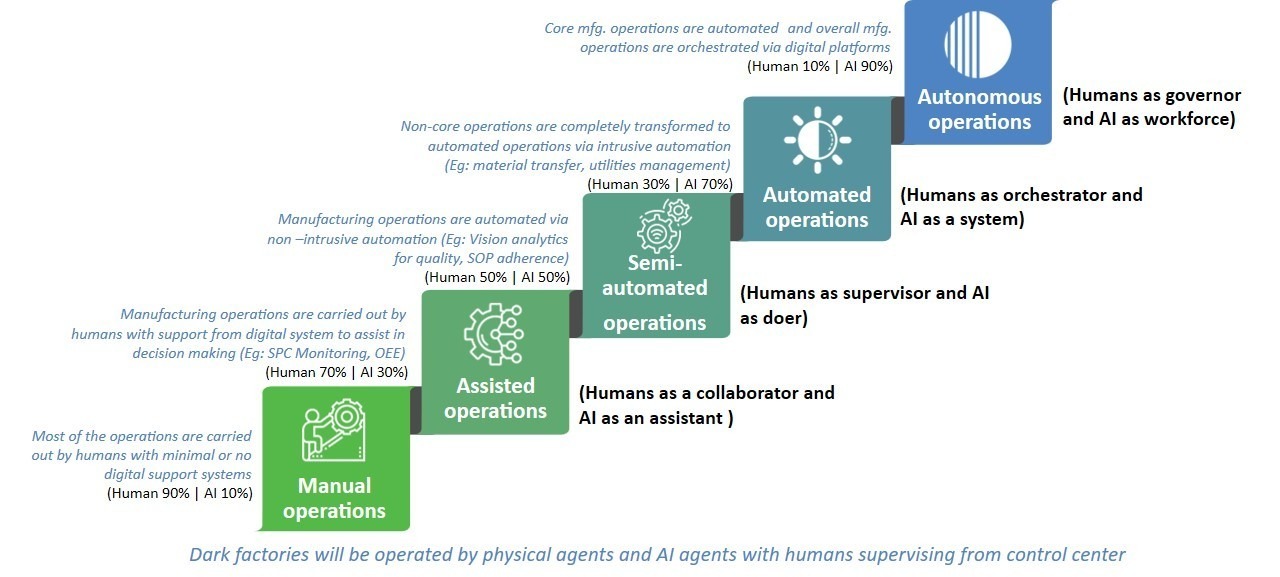

Dark factories do not take shape overnight; it’s a strategic evolution toward intelligent manufacturing. Organisations progress through a series of transformative stages, often implementing multiple initiatives in parallel to meet operational needs. This journey is defined by a gradual shift from human-driven processes to AI-enabled intelligence.

It begins with manual operations, where human effort prevails, and technological support is minimal. Over time, advanced systems augment decision-making, enabling humans and AI to collaborate effectively. As intelligence deepens, humans transition from collaborators to supervisors, while AI assumes execution roles. Eventually, operations are orchestrated by integrated platforms, with humans providing oversight and governance. At the pinnacle lies the autonomous “dark factory,” where AI functions as the primary workforce and humans focus on strategic direction.

This transformation is not simply about replacing human effort—it is about reimagining roles, leveraging data-driven insights, and creating a symbiotic relationship between human judgment and AI. The goal is an ecosystem where efficiency, precision, and adaptability are driven by intelligence, while human vision ensures resilience and innovation.

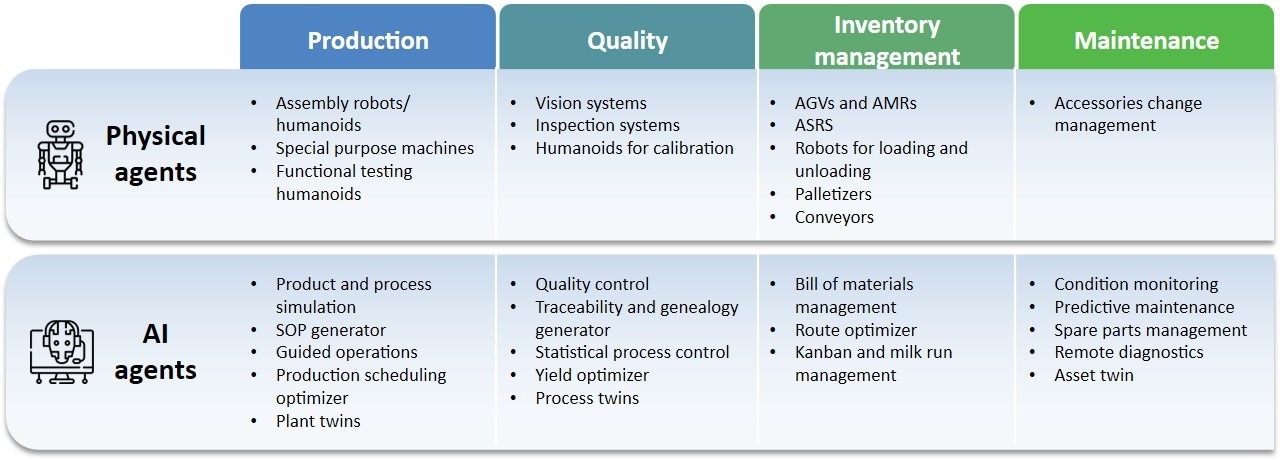

Physical agents are equipment/devices such as Robots, AGVs, AMRs, SPMs, Robot dogs, and Vision systems, performing manufacturing operations autonomously with inputs from the command center and synchronizing their operations by communicating with each other.

AI agents are virtual agents that execute repeated, autonomous manufacturing operations, such as recipe management, SPC monitoring, process parameter optimisation, triggering material requests, and inventory management.

Within each stage, AI and physical agents expand their roles—from providing insights and prescriptions to executing tasks and coordinating cross‑functional interactions. Examples include assembly robots/humanoids, autonomous inspection systems, plant/process twins, SOP generators, and scheduling optimizers, all learning continuously from data and analytics.

Illustrative example: AI agents optimise energy usage (e.g., smart grids) by gathering real-time data from energy consumers (e.g., utilities, compressors, HVAC systems) and manufacturing assets. Smart grids accurately forecast energy demand over days, weeks, or months. Consequently, smart grids enhance energy cost efficiency by optimally balancing conventional electricity with renewable energy sources based on these forecasts. Additionally, in open-market electricity purchases, smart grids provide electricity distributors with strategic recommendations to improve their purchasing plans. These benefits increase from autonomous actions and intelligent commands on the edge, making plants more responsive and resilient.

Pivotal pillars

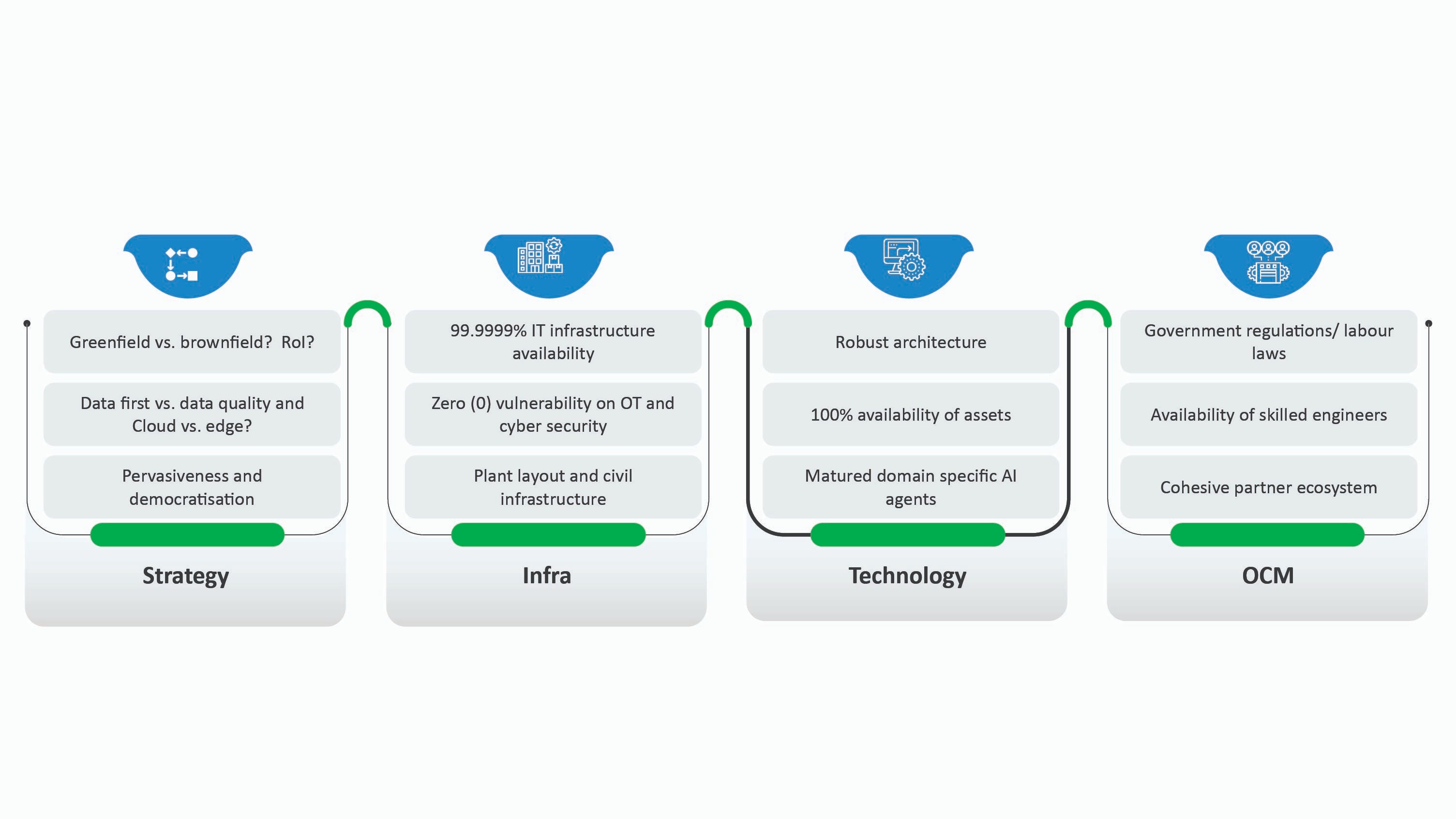

Implementing a dark factory is not a single technology implementation; it is an architectural and organisational commitment. The following considerations provide an actionable checklist.

Strategy - To build a resilient, AI‑first architecture for autonomous operations, organizations must address several foundational strategic questions early—most importantly, whether to pursue a greenfield or brownfield path. This decision is fundamentally a business choice, and the overall approach will vary accordingly. Some key considerations include:

- How to balance data readiness with data quality for AI

- Division of workloads between cloud and edge

- Seamless integration with existing systems like MES/SCADA/ERP/PLM

- Democratizing AI access across all roles,

- Scaling from proof of concept to full rollout

- Robustly calculating ROI at both use-case and program levels

Considering these factors and utilising foundation and domain models, secure infrastructure, and responsible AI safeguards establishes a foundation for lasting value and operational excellence.

- Infrastructure and plant layout - Dark factories demand 100% availability of robotics and automation, with near‑zero tolerance for infrastructure failure. Plant layout, civil works, utilities, and safety systems must be re‑reengineered to suit autonomous flows (e.g., AGV lanes, ASRS integration, autonomous inspection cells) and to accommodate remote human oversight.

- Operational cyber security - Dark factories depend on autonomous interactions, cybersecurity becomes a first‑order reliability concern, not merely a compliance checkbox. Achieving “zero vulnerability” in OT means segmenting networks, enforcing least‑privilege access, continuous anomaly detection, and secure firmware/software lifecycles for robots, cobots, and controllers.

- Technology and architecture - An AI‑first architecture delivers long-term sustainability for AI solutions. Core elements include foundation models, domain‑specific AI agents, retrieval‑augmented generation for engineering knowledge search, parameter‑efficient fine‑tuning, guardrails for responsible AI, and secure data architectures spanning DWHs, data lakes, structured/unstructured repositories, and OT/IT systems. Orchestration layers must support human‑in‑the‑loop task agents and co‑pilots, with edge compute for low‑latency autonomy, resilient networks, and privacy/security controls.

- Organisation changes management (OCM) and talent. As roles evolve (from human as collaborator to supervisor, progressing to an orchestrator, and finally to governor), OCM must guide workforce transitions through reskilling, new operating procedures, and performance management tuned to autonomous contexts. Practical considerations for implementing AI widely across both blue- and white-collar positions, facilitating user adoption without technical barriers, and engaging business teams early to encourage acceptance.

- Regulatory and governance- Different demands based on geography and industry regarding labor laws, machine safety standards, environmental rules, and ethical AI principles need to be considered from the start. Program governance should encompass compliance tracking, the ability to audit AI decisions, and clear incident response procedures developed in collaboration with partners and suppliers.

- Partner ecosystem - A cohesive ecosystem of robotics OEMs, system integrators, AI platform providers, cloud/edge vendors, and cybersecurity partners is essential. Given the breadth and depth of automation required, no single vendor can deliver end‑to‑end capabilities; success depends on robust integration, SLA alignment, and joint value realisation models. Equal emphasis should be placed on enhancing AI solutions and making them accessible for broader application across various industry sectors. Partner collaboration is essential to expand AI solutions while ensuring their protection against cyber threats.

Adaptive by design

The realisation of dark factories has a significant positive impact on businesses, customers, and society.

Efficiency and cost - Dark factories improve OEE, significantly reduce rework, and eliminate human‑efficiency losses through mechanisation and autonomy. AI agents provide real‑time prescriptions for process optimisation, ensuring throughput stability and quality conformance. ASRS, AGVs/AMRs, robotic assembly, and autonomous inspection reduce material-handling time, accelerate flow, and stabilise takt. The result is lower unit costs and more predictable capacity.

Quality and compliance - Vision analytics, statistical process control, traceability, and genealogy generators enable end‑to‑end quality governance. Digital twins of processes and equipment predict deviations and simulate corrective actions before failure modes manifest, while automated calibration and functional testing by humanoids/robots standardize conformance across shifts.

Resilience and scalability. Autonomous operations allow plants to operate 24×7 with less sensitivity to labour availability and shift scheduling. Combined with real‑time inventory, route optimization, and dynamic scheduling, dark factories scale output and adapt quickly to product mix changes. This agility is critical for rapid NPI and segmented demand.

Sustainability and safety. Smart energy management lowers consumption and can align production loads to cleaner energy windows. Removing humans from hazardous zones and elevating them to control‑room roles reduces incidents and enables safer interventions (e.g., remote diagnostics on asset twins, predictive maintenance scheduling to avoid catastrophic failures).

Societal implications. While dark factories promise efficiency and safety, their deployment must be balanced with workforce strategies - reskilling, redeployment, and transparent communication. The ethical use of AI, data privacy, and equitable access to new opportunities must be embedded into transformation programs to avoid adverse social impacts.

In conclusion, dark factories represent an integrated transformation across technology, operations, and organization. The payoff—speed, quality, cost, safety, and sustainability—arises from the synergy of physical automation with AI‑orchestrated workflows and data‑driven learning. Success depends on architectural rigor, cybersecurity, ecosystem collaboration, and human‑centric change management. By adopting a staged maturity path, investing in AI‑first foundations, and tackling strategy questions early, manufacturers can realize a future in which plants truly “think, feel, and act”, delivering resilient, responsible, and scalable value.

Although dark factories address many contemporary industrial challenges, they require substantial upfront investment and must navigate complex regulatory landscapes. As a result, a thorough, carefully structured assessment is essential before advancing toward a strategic deployment.