Industries

HIGHLIGHTS

- Operational fragmentation across countries because of incompatible IT systems, infrastructure and regulations is a major challenge. To achieve seamless rail network requires interoperability, shared data standards, and unified platforms.

- Stakeholders such as rail operators, technology providers, logistics companies, and regulators need to create a connected digital ecosystem through data marketplaces, smart infrastructure, and AI-powered decision systems.

- Modernizing freight railways through digital technologies like AI, IoT, data platforms, 5G, blockchain and automation is essential to improve safety, reliability, sustainability and competitiveness.

On this page

The case for freight rail

The importance of freight rail will only grow in future.

This is because of the increased focus on sustainability and carbon emissions, and the need to optimize logistics. Freight rail is also critical for transporting bulk items such as chemicals, coal, and other raw materials. An efficient freight rail system improves supply chain resilience and economic competitiveness of businesses.

Freight railway organizations are considering digitalization for inclusive transformation of traditional operations by integrating data-driven processes and digital technologies that will address the unique requirements of freight rails.

Many rail companies have, in fact, initiated digitalization programs. These include DB Cargo's Digitalization Program (Germany), SNCF's Digital Transformation Plan (France), OBB's Digital Rail Austria initiative, and SBB Cargo's Digitalization Strategy (Switzerland).

Pain points

Each country has its own technical, signaling, electrification, and safety standards for rail operations.

Various disparities reflect the diverse infrastructural and economic priorities across the European Union (EU). This makes rail transport less competitive than road, which can move across regions more seamlessly.

Rail freight operators also face complicated and time-consuming administrative processes such as fragmented regulatory landscape, varied cross border operations such as customs procedures, safety certifications, and documentation requirements. Besides, many freight rail systems in the EU have legacy technologies with outdated operational practices not optimized for modern freight requirements such as on-time deliveries, supply chain visibility, and seamless intermodal and multi-modal operations. Therefore, there is a need for modernization of the freight railway eco-system. Also, the freight rail industry faces other challenges such as changing trade patterns and capacity constraints.

The lack of coordination between different transportation modes, the absence of standardized systems and processes, and inadequate investments in intermodal terminals hamper the effective transfer of goods between modes. The key barriers to the rapid adoption of digitalization are high latency and low communication bandwidths. The slow progress of digitalization makes the rail freight sector less competitive. However, these challenges present opportunities for innovation and collaboration.

Game changers

Many organizations are addressing these challenges to position rail as a key component of the modern transportation eco-system and improve freight rail demand.

European Union Agency for Railways (ERA), the Europe Rail Joint Undertaking, the European Commission, the International Union of Railways (UIC), Rail Net Europe (RNE), and the European Rail Freight Association (ERFA) are working towards achieving the goals and objectives of European freight railways.

Digitalization and open data initiatives simplify administrative procedures, making it easier for small and medium rail operators to compete with big. By enhancing transparency, efficiency, and cost-effectiveness, digital tools create a fairer, more competitive rail freight ecosystem, for instance, digital freight platforms simplify access to shared information such as rail paths, schedules, infrastructure availability etc. allowing operators to compete.

Digitalization, the next frontier for freight rail

Digitalization facilitates the automation, collection, integration, processing, and analysis of freight rail transport data from various sources, such as sensors in rolling stock, cargo, tracks and bridges infrastructure.

Advanced analytics are leveraged to develop actionable insights from this data, facilitating enhanced decision-making.

Digitalization for freight railways represents a holistic approach to modernizing operations, driven by technology and data enabling customers with real-time access to information about their shipments, improving transparency and communication promoting collaboration among various stakeholders and enhancing integration of freight railways within the broader supply chain. It aids sustainable practices by optimizing resource use and availability, reducing emissions, and improving energy efficiency. Data-driven insights can lead to efficient routing and maintenance practices contributing to environmental goals. Real-time data can help detect and minimize potential safety hazards.

Collaborative ecosystem

Freight rail ecosystem consists of several stakeholders—shippers, operators, infrastructure providers, governance bodies, among others.

With the right infrastructure, analytics, and interfaces, these stakeholders can leverage data to optimize maintenance costs, operations, and overall productivity.

The collection of data, aggregation, and ensuring its compatibility for all stakeholders is only a foundational activity that provides basic information for decision-making. To create further value, insights from the data have to be applied effectively. This is possible through an application layer that utilizes techniques such as artificial intelligence-machine learning (Al-ML) and other analytics to help rail companies improve operations and reduce costs. There is greater potential for value-creation when data, analytics, and software are unified in the form of data products (APIs, datasets, and dashboards). The base data and the data products can be commoditized as partners can leverage these services for value creation.

To achieve maximum value from digitalization, one of the key requirements is to enable collaboration, industry-wide partnerships, and talent development. Collaboration involves industry-wide information and data sharing through common data platforms, standardization of data and communication protocols for seamless data exchange, and an open innovation ecosystem. Industry-wide partnerships enable strategic alliances between rail operators, suppliers, and tech providers. Additionally, industry associations and forums can facilitate industrywide frameworks for data-sharing, cybersecurity, and process standardization. Talent development will require enhancing digital skills through training to handle and address the digital skill gaps and the digital transformation requirements.

Freight rail's digital tomorrow

A digital tomorrow is poised to transform freight rail and the railway industry.

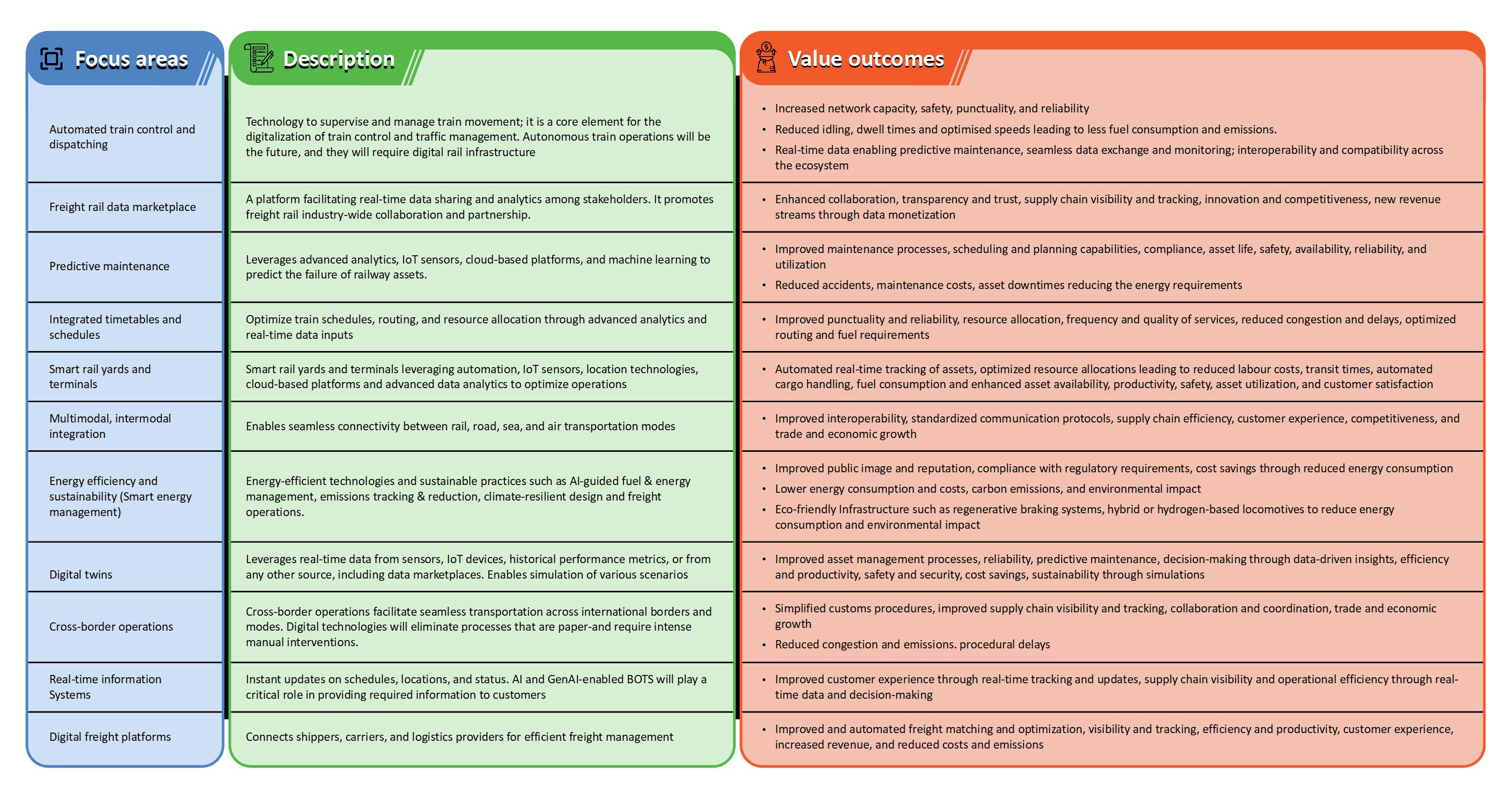

As the industry continues to evolve, railways must invest in digital infrastructure, address cybersecurity threats, and develop new business models to remain competitive. In an industry characterized by various business functionalities and vast amounts of data generated from various sources, focus on certain priority areas will unlock immense value (see Table 1).

Despite the challenges, the future potential of digitalization is huge, offering a conduit for interconnected and data-driven freight railway ecosystem. Integrating advanced technologies like AI-ML, Gen AI, Agentic AI, quantization, 5G, edge computing and blockchain will enhance its value proposition. For instance, AI can analyze complex datasets to provide predictive insights. Gen AI can augment existing datasets by creating synthetic data that fills gaps or improves the quality of available information, while blockchain can ensure data integrity and traceability.

Agentic AI systems are capable of autonomous decision-making, continuous learning, and proactive adaptation, can revolutionize digital freight rail by self-managing operations, optimizing logistics, enhancing safety, and improving sustainability. Industry believes that, with Agentic AI, freight railways can dynamically adjust train routes based on live data from weather conditions, track congestion, energy consumption, and market demand and minimize reliance on human intervention, reducing costs and improving reliability.

Freight railways can unlock new possibilities for digitalization, automation, and efficiency by leveraging 5G and edge computing systems enabling real-time ultra fast data processing and exchange for requirements such as freight and asset tracking, automation, and remote inspections and condition monitoring etc. The next phase of digital transformation in freight railways would be defined by integrating AI, automation, IoT, and sustainable energy solutions to create an intelligent, fully connected, and autonomous freight rail ecosystem.

Autonomous trains with AI-driven operations, ultra-fast connectivity, and green technologies will transform freight rail into a hyper-efficient, competitive, sustainable, and future-ready transport system. As the industry continues to evolve, embracing latest technologies will be crucial for maintaining competitiveness and sustainability in an increasingly digital world.

Partners in the digitalization journey

Freight railways can leverage support from technology providers, system integrators, academicians, industry associations and original equipment manufacturers (OEMs) to realize the potential of digital technologies.

These partners play a vital role in facilitating freight railways achieve digitalization goals by integrating disparate systems, diverse technologies, and automation of processes for seamless operations, improved efficiency and capacity, and enhanced customer experience, thus enabling competitiveness. Focused investment in technology, cybersecurity measures, and commitment to change management will further enable the industry to thrive in a digital future. The successful implementation of digital technologies will define the next generation of freight rail, ensuring that it meets the demands of modern logistics.