Products and Platforms

Highlights

- Packaging waste is a major environmental burden, contributing to ocean pollution, clogged waterways, and growing landfill pressure.

- Policymakers face persistent challenges as packaging waste continues to strain ecological systems and exacerbate global waste‑management issues.

- PPWR offers a comprehensive lifecycle‑based framework to reduce, manage, and regulate packaging waste, strengthening environmental protection through redesign, reduction, reuse, and recycling.

On this page

The packaging burden

Waste management presents one of the most formidable environmental challenges of our era. From vast flotillas of waste drifting across oceans to clogged waterways and mounting heaps of rubbish encircling urban centres, the issue poses persistent difficulties for policymakers. Among the chief contributors to this crisis is packaging waste, which creates significant strain on ecological systems.

To address these concerns, the newly implemented packaging and packaging waste regulation (PPWR) emerges as a critical tool for safeguarding the environment. This regulation introduces a comprehensive, multi-pronged strategy for managing packaging and its associated waste throughout its entire lifecycle.

PPWR analysis

PPWR rests on four foundational R’s—Redesigning, reducing, reusing, and recycling as shown in the diagram below. These pillars serve as the framework for tackling packaging-waste challenges.

The four ‘R’ framework

- Redesigning and standardising: Redesigning focuses on creating packaging that is both sustainable and functional. This process examines the characteristics of packaged items, packaging specifications, geometry, dimensions, format restrictions, material composition, and the use of hazardous substances. Redesign also aims to facilitate tracking, reuse, dismantling, segregation, and recycling. Evaluating whether a design meets its objectives can be accomplished via an eco-design assessment. PPWR, specifically Annexure II, Table 3, and Article 6, outlines the criteria for assigning recyclability grades and the standards for hazardous materials, including PFAS content. Article 12 further outlines requirements for labeling and the integration of tracking mechanisms such as QR codes.

- Reduction and prevention: Reducing packaging waste is addressed in Article 10 and Annexure IV, which stipulate ratios to minimise package space, capping it at 50% above the space occupied by the packaged item. Computing weight-ratio measurements is also prescribed. Preventive measures focus on the use of specific materials and formats, as highlighted in Annexure 5, Articles 24 and 25. Article 34 proscribes single-use plastic carry bags, while Articles 42 and 43 expand on waste prevention strategies.

- Reuse and refill: Encouraging reuse and refill processes further reduces packaging waste. Article 11, along with Articles 26 to 33, offers detailed guidance. Deposit, collection, and return systems are governed by Articles 48 to 51, while Article 55 establishes information systems to support reuse and refill operations.

- Recycling and composting: PPWR devotes considerable attention to promoting recycling. Articles 6 to 9 set recyclability requirements, mandate minimum recycled content (Article 7), address biobased plastic feedstocks (Article 8), and provide composting guidance (Article 9 and Annexure III). Methodologies for estimating recycling rates and tracking progress against prescribed targets are outlined in Articles 52, 53, and 54.

PPWR essentials

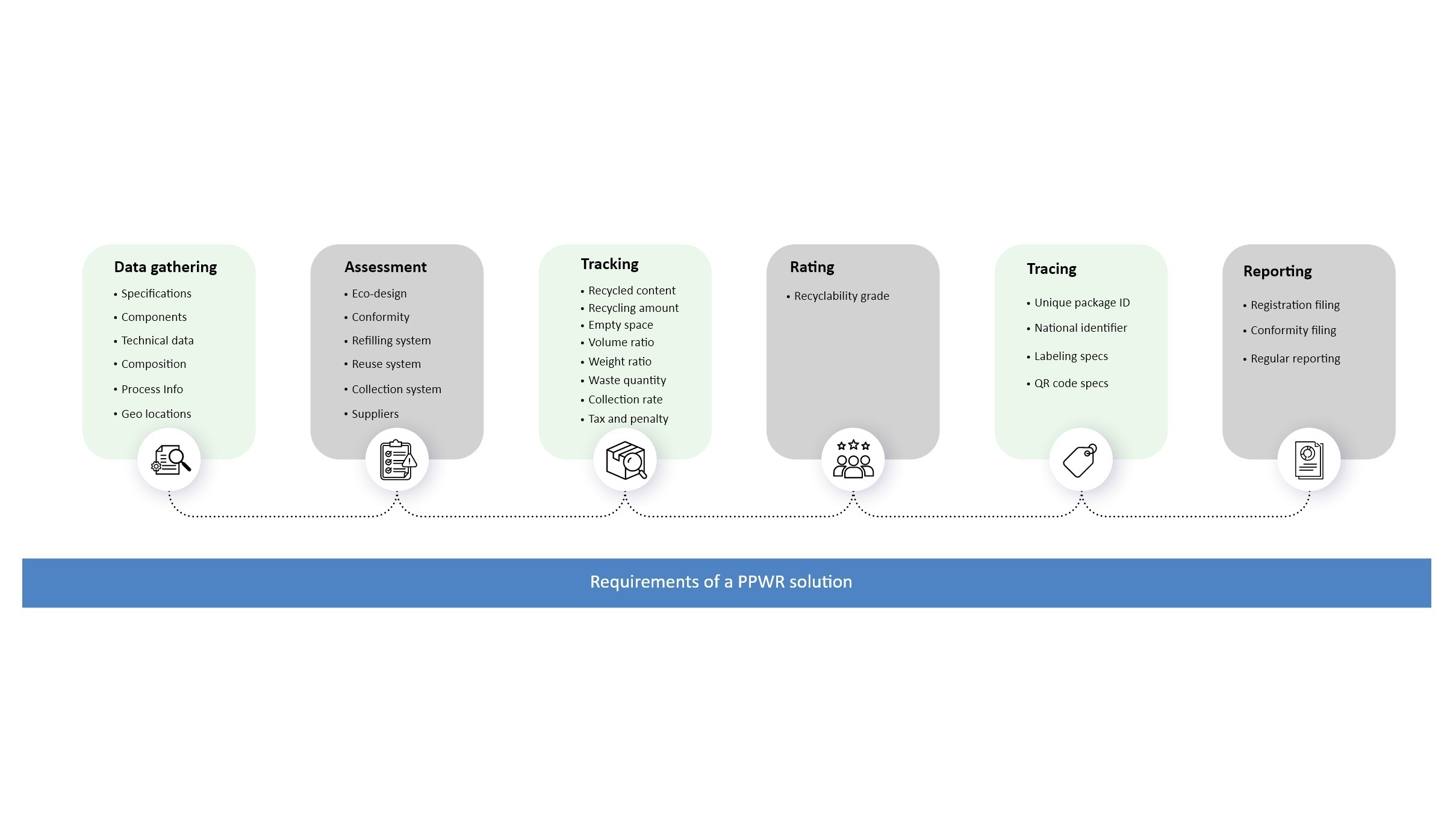

Analysis of PPWR provisions reveals six essential solution feature requirements as shown in the diagram above:

- Data gathering: Comprehensive data must be collected on packaging specifications, performance, and lifecycle processes. Sources include internal systems (such as bills of material and master data management) and third parties (vendors, distributors, recyclers, reuse/refill systems, consumers).

- Assessment: A highly configurable platform is required to conduct conformity assessments, evaluate eco-design and hazardous content, and address diverse entities, including suppliers, distributors, and recycling systems. Flexibility is crucial as regulatory parameters evolve.

- Tracking: Ongoing tracking of performance, risk, and compliance metrics is essential. Indicators, such as volumetric and weight ratios, recyclability percentages, and trip counts, should be visualised through charts and self-serve dashboards. Effective tracking enables timely alerts and issue registration, with agentic AI supporting action-plan triggers.

- Rating: Many assessments require generating scores and ratings to inform decision-making. This includes recyclability ratings, as well as supplier, reuse system, and refilling station scores. Sophisticated modeling may be needed to reflect organisational specifics.

- Tracing: PPWR aligns with product eco-design guidelines on embedding traceability in packages, much like the concept of a digital product passport. Requirements have been laid down for placing specific pictograms, QR codes (or other similar mechanisms) on labels to facilitate required disclosures and traceability. Packages need to carry a unique identifier, type, trademark, national identifier for the producer/producer organisation, and batch number/serial number, much like a digital product passport. The QR code needs to provide much more information, such as component-wise composition, concentration by hazardous material, component by destination, and the like.

- Disclosure and reporting: The PPWR solution is also required to make information submissions comprising measurements of packaging and packaging waste, as per the table structures specified in annexure II and annexure XII.

Besides, producers and producer organisations need to submit the prescribed information for registration and should also submit an EU conformity affidavit when placing a package on the market.

Solution proposed

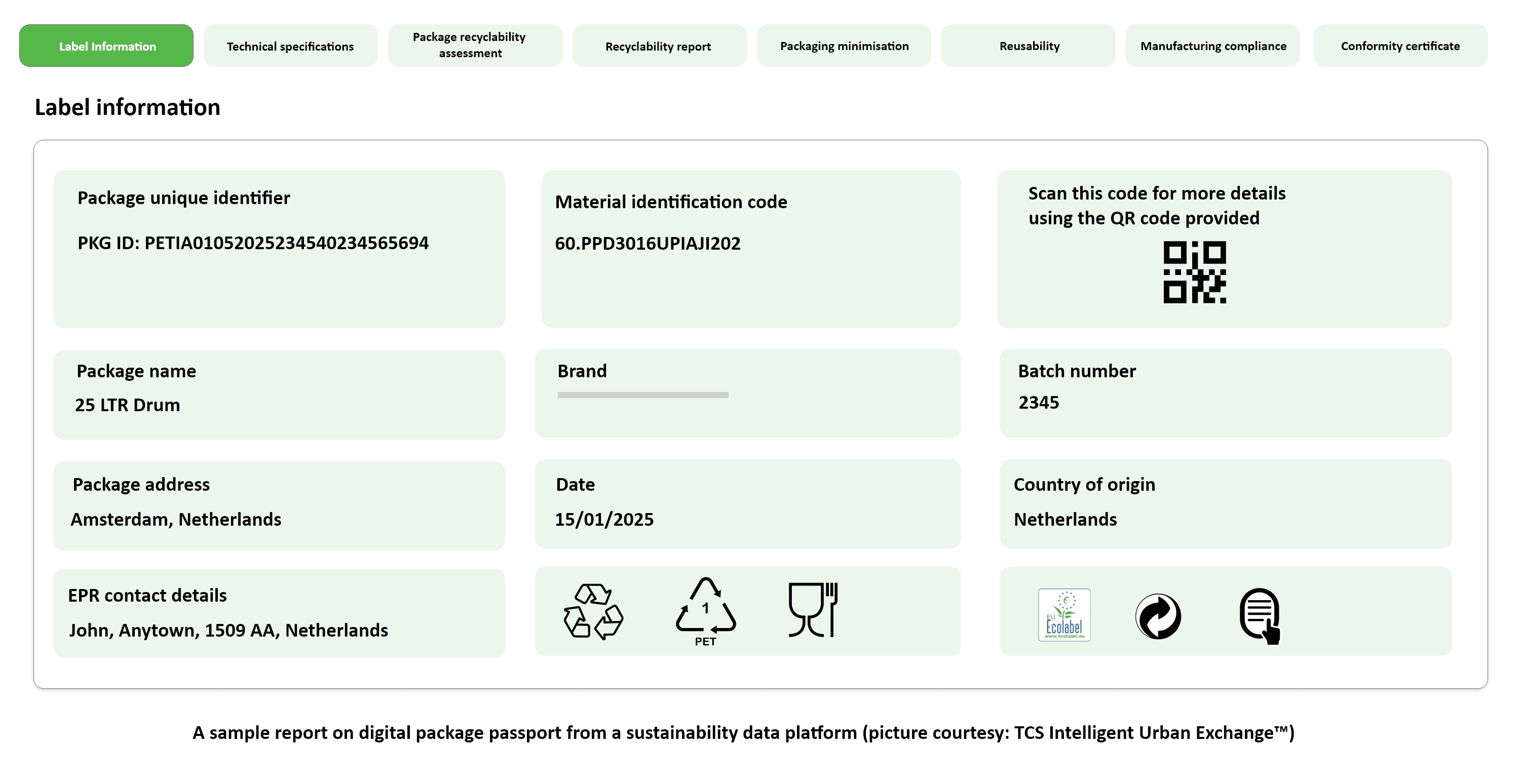

To address these requirements for a PPWR, a comprehensive packaging lifecycle management solution, such as the digital product passport, is recommended. A “digital package passport” providing comprehensive visibility into various aspects of a package across each stage of the packaging lifecycle, along with the desired management information system (MIS) and regulatory reports, can be most appropriate in this context.

The digital packaging passport, as shown in the picture, provides all handlers with the necessary information. It provides through-and-through visibility, on a need-to-know basis, into the supply chain, design, specifications, conformity, support network, chain of custody, handling, performance, repair, repurpose, and end-of-life treatment through a cradle-to-cradle circular journey.

Sample MIS report

As such, providing access to such information requires putting in place an appropriate mechanism to capture and disseminate such information. Wherever feasible, based on the packaging's nature, incorporating Internet of Things devices and RFID technology to capture and collect data is recommended. For example, such devices can help gather custodial information such as location, ownership, activities packages are subjected to, and package performance metrics. Similarly, captured information can be disseminated by providing access to the Digital Package Passport via a QR code on the package label that includes a unique Package ID and the package portal URL. For example, by scanning the QR code, a user of the product can access information on safe disposal of the package and network access for handover of the discarded package, based on its specifications. If the package is available for reuse and refill, the product user can access information on how to do so safely and when to discard it. Likewise, a recycler will have access to information on material composition, the recycling process, required safety measures, the reintroduction of recovered material, network access, and so on.

Additionally, incorporates a value chain knowledge graph based on the captured chain-of-custody information. Alternatively, distributed ledger technology (blockchain) can be used to build traceability throughout the supply chain. This way, the digital package passport can deliver on the twin objectives of capturing and disseminating information.

The second cog in the PPWR solution is an MIS powered by artificial intelligence and machine learning. Packaging MIS serves as a decision support system to help achieve the objective of efficient and effective packaging cycle management. For example, MIS analytics generating recommendations on carbon and environmental footprint management in sourcing and across the entire packaging value chain is imperative. Recommendations on adjusted input pricing for the indirect costs associated with carbon footprint and ecological footprint are very much warranted. MIS reports can help track and monitor the number of refurbishments and refills, and the need for intervention for refurbishment, if any.

MIS reports comprising heat maps, trend charts, peer comparison, package performance, clustering analytics, and packaging mix drive a range of business decisions.

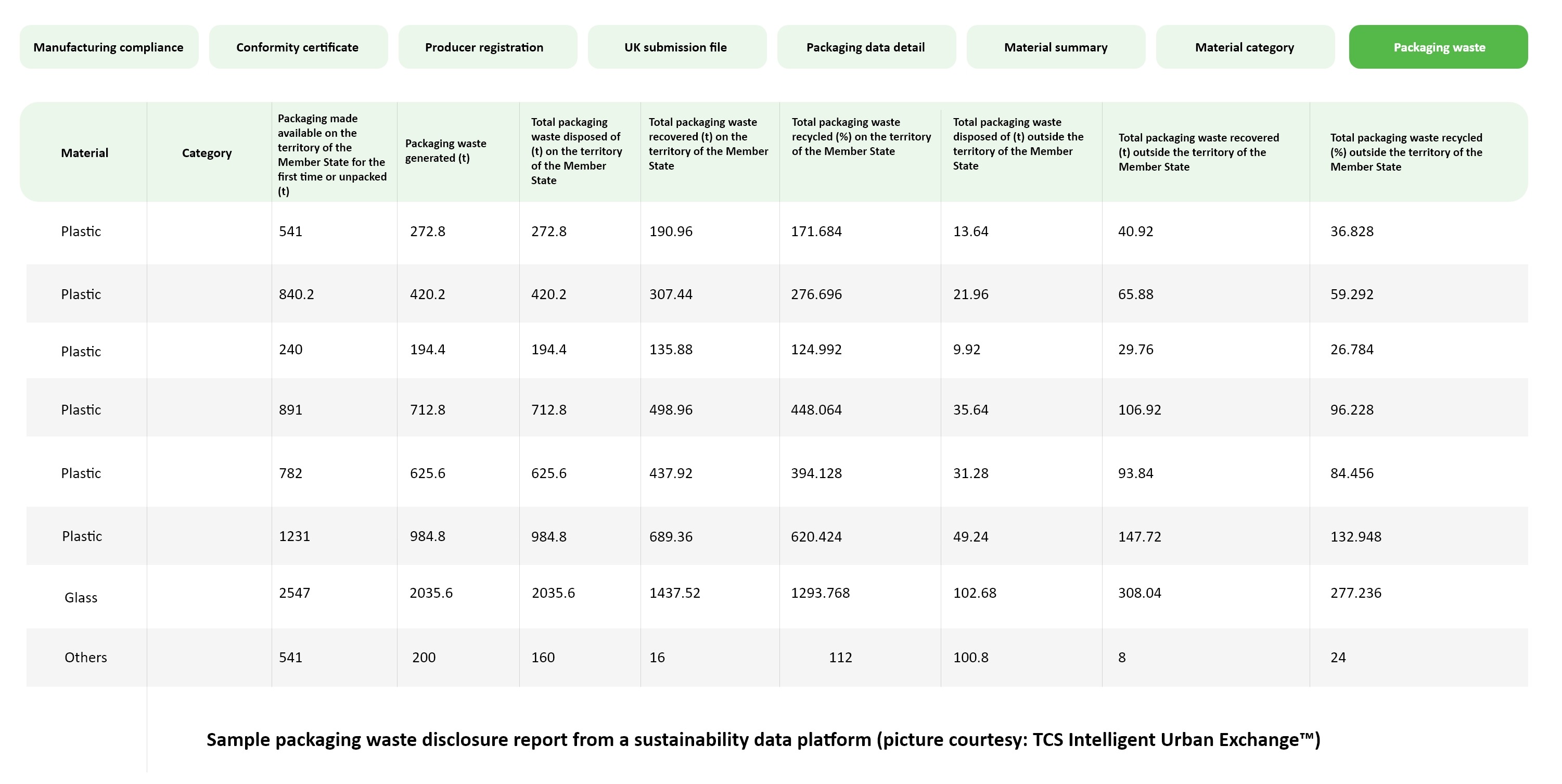

Regulatory reporting, on the other hand, focuses on compliance with the disclosure and filing requirements set out in PPWR, as shown in the picture here. Such reporting enables regulators, other authorities, and broader markets to fulfill their responsibilities better. Authorities tasked with protecting environments and preserving the use of scarce resources can better perform their duties by using data on packaging and packaging waste at the national level. For example, having information on waste recycled versus diverted to landfills is crucial for planning waste-disposal infrastructure. Similarly, data on recyclable packages placed in the market vis-à-vis the recyclability achieved shows the efficiency of the package waste management infrastructure and provides necessary insights for improving it.

Conclusion

In summary, the PPWR establishes a comprehensive framework for sustainable packaging by outlining robust requirements across recyclability, assessment, monitoring, scoring, traceability, and disclosure. Success under this regulation demands not only technological integration and flexible assessment platforms but also a commitment to transparency and continual improvement. By meeting these multifaceted requirements, organisations can ensure compliance, demonstrate environmental responsibility, and position themselves as leaders in the evolving circular economy landscape.