Services

Highlights

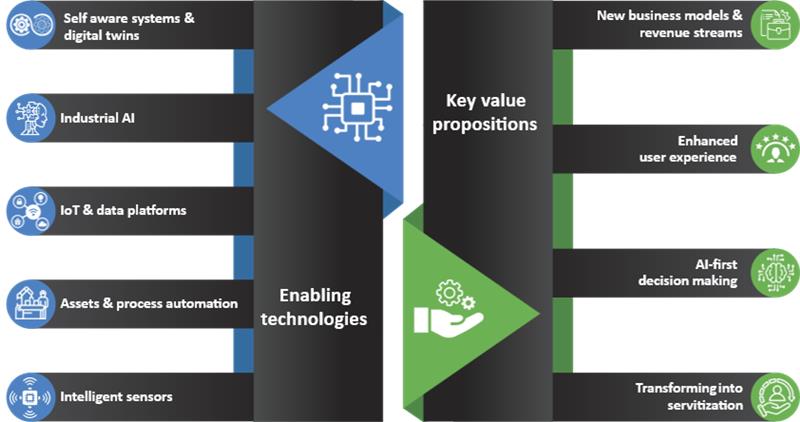

- Enterprises encounter significant challenges in a competitive landscape characterized by the commoditization of products, evolving customer demands, declining profit margins, and the imperative to maintain their market leadership.

- The S2C IoT platform transcends mere connectivity; it focuses on transforming physical assets and software into intelligent, collaborative ecosystems.

- By integrating physical context with digital intelligence, businesses can discover new business models, provide personalised experiences, and facilitate AI-driven decision-making.

On this page

The tectonic shift

Today’s enterprises operate within a dynamic and highly interconnected market landscape. Product commoditization, decreasing profit margins, and escalating customer expectations have made conventional product-focused models outdated. Companies can no longer set themselves apart solely through great hardware and product features—they are now required to provide ongoing value, immediate responsiveness, and tailored experiences.

This shift is fueled by five converging forces:

- Digital-physical convergence: The physical world is now equipped with sensors that produce real-time data—connecting the physical and digital realms.

- Customer expectations: Both B2B and B2C customers expect quicker service, enhanced transparency, and proactive assistance.

- Cost pressures: The maintenance of extensive CapEx-heavy infrastructures no longer offers a competitive edge. Rather, adaptable, usage-based OpEx models are becoming more prevalent.

- Regulatory complexity: Compliance and sustainability mandates require traceability and accountability at every point in the value chain.

- AI and cloud maturity: The increasing sophistication of industrial AI, edge computing, and cloud-native frameworks has made it both technically and economically viable to oversee, analyse, and manage extensive networks of physical assets in real time.

Sensor-to-Cloud (S2C) IoT platforms serve as the cornerstone of this transformation. By integrating intelligence into tangible assets and linking them to the cloud, organisations establish a closed-loop system that perceives, learns, adjusts, and continuously evolves. This represents more than mere digital transformation; it embodies the intelligent orchestration of products, processes, and individuals.

The platform paradigm

To stay competitive, enterprises need a platform that captures real-time data at the edge, fueling analytics, automation, and intelligent decisions across the system.

A sensor-to-cloud platform offers much more than just IoT connectivity. A complex, multi-layered architecture is crucial as it meets the challenges of complexity, scale, security, and performance that are characteristic of contemporary IoT systems. It divides the system into distinct, manageable layers, with each level tasked with functions such as sensing, data gathering, processing, cloud analytics, AI engines, and the delivery of business applications. This is in stark contrast to a basic, monolithic architecture that would struggle to cope with the scale and variety of IoT.

Below is a typical outline of how the architecture is structured:

- Edge layer: This is the stage where data is produced, and sensors are located on machines, in environments, on people, or on products. This category encompasses vibration sensors, temperature sensors, vision systems, wearables, and additional devices.

- Gateway and connectivity layer: At this level, data undergoes pre-processing, filtering, and secure transmission via 5G, LPWAN, Wi-Fi 6, or private LTE networks.

- IoT cloud platform: This serves as the hub for centralised processing of both real-time and historical data, facilitating integration with enterprise systems such as ERP, EAM, and MES, and the orchestration of workflows.

- AI and GenAI for physical assets: This layer utilises advanced analytics to provide predictive insights, anomaly detection, generative diagnostics, and prescriptive recommendations.

- Service enablement layer: This layer facilitates field service automation, performance dashboards, digital twins, remote troubleshooting, and services that can be monetised.

TCS's bringing life to things framework leverages this architecture to assist enterprises in:

- Transforming static products into intelligent, self-aware assets

- Minimising downtime and maintenance expenses through predictive diagnostics

- Improving sustainability by optimising resource utilisation

- Transitioning from product sales to value-added service delivery

The strength of this approach lies in its adaptability; it is not a one-size-fits-all solution. It is modular, verticalized, and designed for interoperability between both legacy and modern systems.

Proof in action

The S2C paradigm represents not just a technological shift, but also a method to unveil new service and asset-oriented models, thereby delivering continuous value.

The S2C IoT solutions enable intelligent, data-driven transformation use-cases across various themes, including connected production, predictive maintenance, energy optimisation, smart grid management, smart stores, connected care, transportation, urban IoT solutions, and precision farming, thereby improving efficiency, sustainability, and growth.

A few examples of how an S2C IoT platform enables industry-specific applications and services:

Connected products, platforms and servitization

Connected products are tangible assets equipped with sensors, connectivity, and intelligence, which allow them to gather and transmit operational data in real time. Servitization changes these products from one-time sales into ongoing service offerings — such as pay-per-use, subscription, or performance-based contracts — providing continuous value to customers. There is a need to assist manufacturers and OEMs in embedding IoT sensors, establishing secure connectivity, and integrating edge/cloud analytics to oversee product performance, anticipate failures, and facilitate remote diagnostics. The associated frameworks enable firmware-over-the-air (FOTA) updates, product personalization, and AI-driven service recommendations. By merging engineering, platform integration, and business model consulting, it enables enterprises to shift from capex-led sales to sustainable Opex-driven revenue streams.

For instance, a European heavy equipment manufacturer integrated the S2C IoT platform to decrease unplanned downtime by 40% through real-time asset health monitoring.

Connected supply chain

Connected supply chain leverages IoT, analytics, and automation to ensure comprehensive visibility throughout procurement, manufacturing, logistics, and delivery processes. The sensor networks, RFID tags, GPS trackers, and temperature/humidity monitors gather real-time data across various supply chain nodes. This information is incorporated into digital twin models for scenario planning and into control tower dashboards for timely intervention. A connected supply chain minimizes losses, elevates service levels, and promotes sustainability by decreasing waste.

One quick scenario, a consumer-packaged goods (CPG) leader utilized S2C to track real-time inventory across third-party logistics (3PL) warehouses, which led to a reduction in spoilage and a 20% improvement in demand forecasting accuracy.

Connected enterprise asset management

Connected enterprise asset management combines conventional asset management with IoT-enabled monitoring and AI-driven predictive maintenance. It offers a comprehensive 360 degree perspective on asset health, utilisation, and lifecycle, allowing organisations to enhance up time and minimise operational expenses. These platforms also ensure compliance with cybersecurity standards and offer scalable deployment across multi-site operations in sectors like energy, utilities, manufacturing, and transportation.

To illustrate, a Canadian pump manufacturer achieved a 30% increase in asset availability by utilizing vibration sensors and edge AI for pump and valve diagnostics.

Smart stores and connected spaces

Smart retail and connected spaces transform physical locations into intelligent, AI data-driven environments that enhance customer experience, improve operational efficiency, and reduce costs. Sensors, cameras, and IoT devices continuously monitor shelves, customer flows, and environmental conditions. Deploying shelf sensors, electronic shelf labels, people counters, HVAC/lighting automation systems, and subsequent integration into a central IoT platform enables retailers to auto-replenish stock, optimize store layouts, and reduce energy consumption.

As an example, A global retailer deployed S2C IoT platform-based lighting and cooling optimization and saved $3.5M annually across 1,000 stores.

Connected care

Connected healthcare utilizes IoT devices, wearables, and sensors to enhance patient care, facilitate remote monitoring, and streamline medical asset management. Deployment of IoT-enabled patient monitoring devices, asset tracking systems, and environmental sensors tailored for pharmaceutical manufacturing and hospital environments deliver real-time insights regarding patient vitals, asset positioning, and essential storage conditions (such as cold chain requirements for vaccines).

Here is a snapshot, a hospital network achieved a 50% reduction in equipment search time by implementing BLE-based asset location tracking integrated into their cloud dashboard.

By utilizing the S2C IoT Platform, businesses can shift from traditional capital expenditure-heavy investments to service-oriented operating models — thus reducing upfront costs, improving scalability, and boosting return on investment over time. Organizations need reliable partners with expertise across various sectors who can support them in developing composable, secure, and scalable solutions that align with their transformation journey — whether it includes pilot projects, enterprise-wide deployments, or customized solutions in energy, retail, logistics, or life sciences or other industries.

Getting started

Initiating the sensor to cloud journey begins with the identification of high-impact assets and relevant use cases.

A phased roadmap — transitioning from connected to predictive and to autonomous operations — guarantees incremental value realization. And this transformation can be facilitated through collaborative ecosystem of IoT accelerators, sensor and device OEMs, cloud alliances, and specialized solutions across sectors such as retail, manufacturing, healthcare, TTH and more.

The path to S2C transformation need not be daunting. Organizations can adopt a crawl-walk-run approach to ensure measurable ROI at each phase:

Step 1: Evaluate readiness Assess the current asset infrastructure, digital maturity, and availability of data. Establish key performance indicators (KPIs) such as uptime, customer experience, and energy cost per unit.

Step 2: Focus on use cases Begin with one to two high-value use cases, such as remote diagnostics, predictive maintenance, or asset tracking. Concentrate on areas that have a direct impact on the business.

Step 3: Establish the foundation Implement edge devices, ensure secure connectivity through 5G or other wireless technologies, and utilize a scalable cloud platform. Integrate these solutions with existing ERP and EAM systems.

Step 4: Foster intelligence Incorporate AI and machine learning models that are trained on asset behavior to enhance predictive capabilities. Utilize Generative AI to facilitate human-machine collaboration, such as assisted maintenance or smart instructions.

Step 5: Expand across enterprise After the initial pilots demonstrate success, broaden the implementation to include multiple sites, assets, or geographical areas. Transition from reactive operations to predictive and to autonomous operations.

By establishing a clear vision and strategy, businesses can identify the most advantageous use cases that yield immediate returns on investment, delivering enhanced benefits while shortening the payback period. Focusing on these use cases allows organizations to optimize the value derived from their Sensor-to-Cloud (S2C) IoT platforms investments and secure a competitive edge.

Through a domain-centric strategy, the transition from sensor to service becomes both seamless and scalable. More significantly, it reveals unique servitization opportunities—enabling organizations to reconsider their approaches to attracting, engaging, and retaining customers through ongoing continuous value delivery.